Author: Supply Chain Transformation Managing Consultant / Supply Chain Management Advisor – Yassin Ibrahim ElGabroni, MBA

The eruption of coronavirus in 2019 brought different challenges. One such challenge was the effect on the global supply chain. Today, companies are striving to reduce these effects, maintain supply chains, and meet increasing customer demands, while being able to react faster to the external disruptions and increasingly complex changing variables along with the current linear economy model.

For instance, due to the increase of patients, facing the symptoms of difficulty to breath, the world has experienced a shortage of medical devices, especially ventilators. The shortage of these devices occurred because of the dependence of one manufacturing part on the other and overall, the elements of the value chain on one another; an unprecedented increase in demand for one product from the consumer side would create a ripple effect down the line through retailer, manufacturer, and materials suppliers, who themselves need to procure raw materials to produce and package the supplies, while logistics and transportation carriers facilitate the movements of goods in different forms between the nods of the supply chain parties. This unforecasted spike in demand creates a pressure that was not accounted for by the end consumer, hence, the inability to fulfill and supply that demand; given the capacity constraints on the production lines, availability of material for production in the new required quantities, and lack of finished product in the Inventories.

Another reason is the distributed and scattered locations of these supply chain elements, which lengthen the supply chain lead & reaction times. The length and complexity of the supply chain network design, are some of the factors that decide the agility and resilience of the supply chain. Overall, this disruption was not limited to medical devices and has impacted almost every sector. No matter whether it’s grocery, garments, or furniture, every sector has faced and is still facing supply chain issues in times of uncertainty or when the supply network is not adaptable and concrete enough.

Therefore, the pandemic has played a catalyst role in channelling investments and transition plans toward the digitalization of corporate functions and structures. It was also an eye-opener to the vast majority of enterprises that in the game of survival among the beasts, there’s no place for the undigitized. More and more steps have been being added to increase efficiency, reduce costs, and uplift revenue while better managing the working capital.

Add trade value with Al technologies

One of the biggest challenges in supply chain management is getting the demand forecast volume right, It all starts from demand, If it’s right, Everything else will follow.

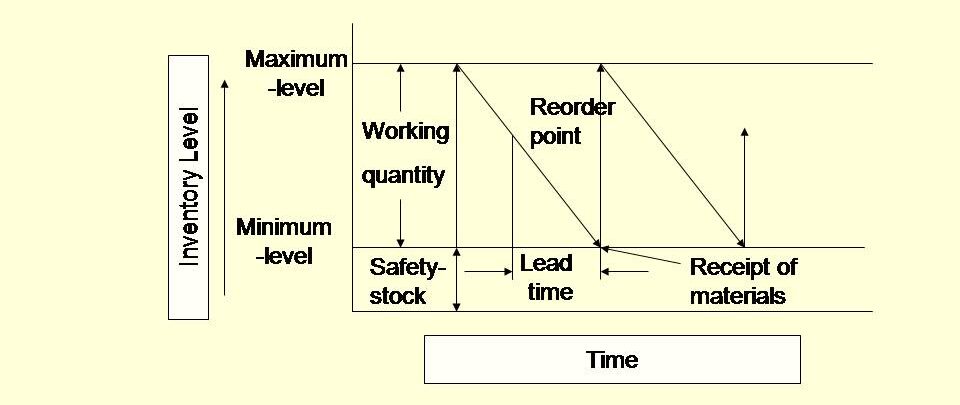

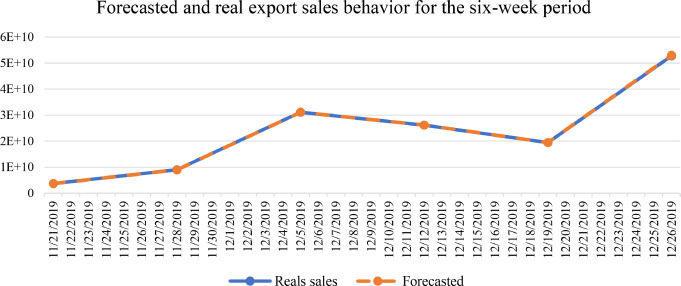

Getting the long-term demand right means that correct rough-cut capacity planning will be done right, which means that the correct amounts of materials will be ordered, stored, and manufactured to produce the finished goods on time for the end consumer. In a perfect world, the inventory would look as shown below in Fig.1, a repetitive identical cycle of stock depletion and replenishment, then the demand forecast values would be identical to the value of the actual order volume as shown in Fig.2

Fig.1 è Inventory control model and replenishment cycle – Perfect conditions.

Fig.2 è Demand forecast Vs. Actual sales – Perfect conditions.

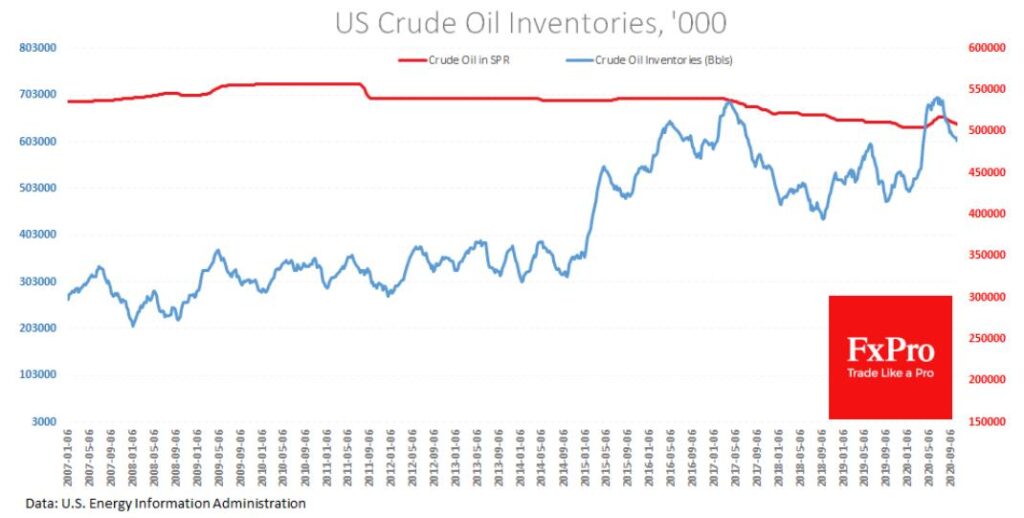

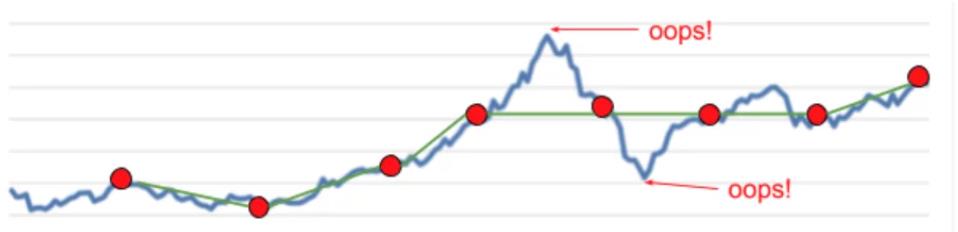

However, as seasonality, trends, production disruptions, lack of materials or transportation capacities, and many other factors make the reality of our world, the product Inventory cycle rather looks as shown in Fig.3, and the demand forecast Vs. The actual volume shipment would be as in Fig.4

Fig.1 è Inventory control model and replenishment cycle – Real conditions.

Fig.4 è Demand forecast Vs. Actual sales –Real conditions.

And this is where Artificial intelligence and machine learning have come a long way to revolutionize demand planning and baseline volume forecast generation, with increased accuracy vs. traditional ways by 10-15 % and an additional 3-12% in the powerful super-advanced multi-algorithm / multi-agent models, additionally, a better prediction of seasonality and shipment trends, spikes, and plateaus. All while increasing the speed and ease of execution, and system interface, enabling integrability with other planning functions, which creates a synergy of synchronized smart systems, driving more efficiency and robustness.

With the help of AI, one can build a digital-twin model of global supply chains, run simulations, and what-If scenarios to respond to different shocks, or validate the correctness of pending decision-making in the supply network design. The usage of Al tools helps in the detection of problematic and dysfunctional parts of the supply chain. All the information thus obtained could be useful for strengthening the market scenarios and be ready long beforehand with the right plans in place, which would significantly enhance the resilience and agility of the whole enterprise.

Add speed & visibility with Blockchain technologies

Another promising technology for supply chain operations is blockchain technology. Here’s how blockchain technology is effective in supply chain management:

- It uses transparent verification and real-time data for determining errors.

- It can resolve all the disputes along the supply chain in time with the help of other features, such as smart contracts.

- Blockchain technology can also streamline payments and record keeping.

- It makes the traceability of transactions much easier.

- Blockchains have immutable nature.

All these features of blockchain make the supply chain more automatized and eliminate third parties and intermediaries by using a shared and synchronized environment, which increases the speed of execution and shortens reaction times, enabling visibility of the interconnected processes in real-time and traceability of product life cycle.

This allows managers to get a precise insightful view of the E2E steps taken, which enables prioritization of actions by business impact and automatically spot the gaps and inefficiencies to drive corrective measures and apply best practices.

Blockchain technology induces working more effectively for the supply chain, where there is a need to verify the transactions by several parties taking into consideration that rule-based activities could be automatically triggered once the clauses of a given contract have been met and matched with current conditions. All while ensuring higher and reinforced security of data and transactions recording, better governance over the involved stakeholders, and building of trust among the involved nodes.

Conclusion: Future of supply chain

Technology and digital solutions are at the heart of innovation and they’re successful in minimizing trade credit risks, delays, and overall costs. They entirely change the supply chain As-Is state towards a new more efficient revolutionary To-Be. And while some technologies like blockchains are blue ocean, way less adopted by the market, and are currently, in the early development stages, it’s believed that blockchain and the other disruptive AI-based technologies now are like the internet 20 years ago and they shall be shaping and paving a new era of enterprise structure and process transformation.